Applications

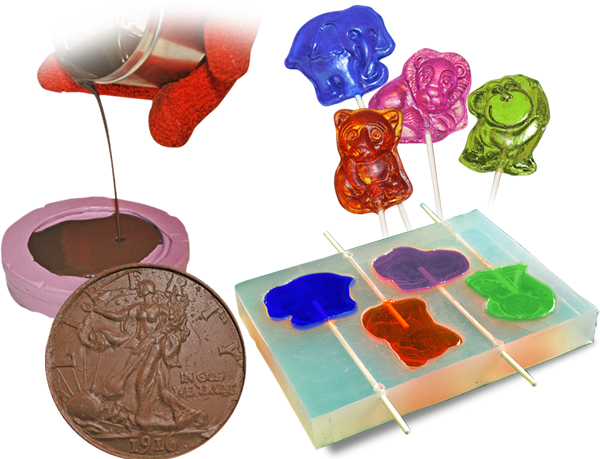

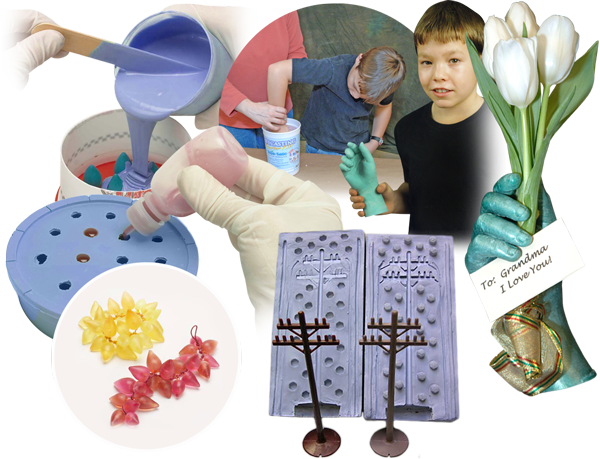

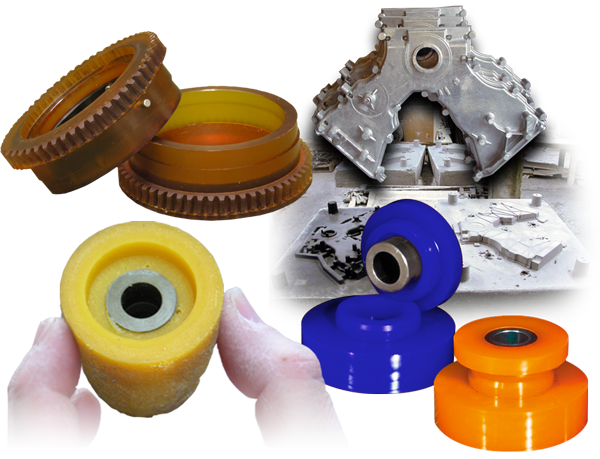

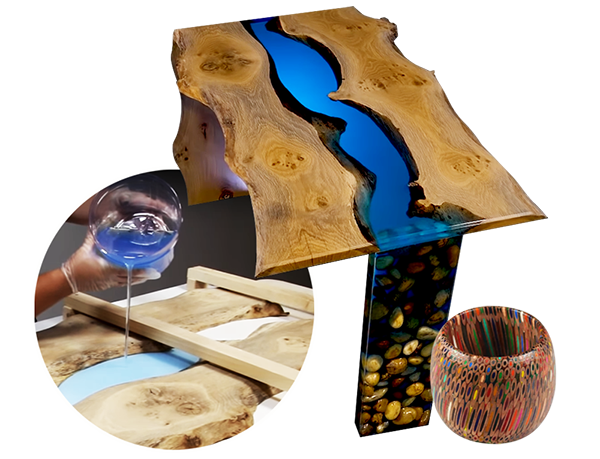

Specialised moulding and casting covers a wide spectrum of activity, from industrial applications through to artistic creations and fabrications.

We stock rubbers, plastics, epoxies, foams, plasters and a whole host of ancillary products to cover all these areas.

Industrial Applications

We can advise on which are the best products for composite moulding, reproduction, prosthetics, bonding, coating, sealing, protection, encapsulation, prototyping, assembly and lubrication.

Creative applications

We supply products across special effects, the arts, life-casting, fashion, design, merchandising and modelling — anything from one-off creations to low volume production runs.